Congratulations! You’ve landed your first remediation/assessment project where PFAS compounds are the concern. Maybe you’ve heard of the different field and testing requirements out there, but it is not clear what they mean, or how to initiate testing. Enthalpy can assist you in the navigation of these regulations and testing requirements. Let’s look at a few important aspects when it comes to PFAS testing:

Due to the extremely low levels of detection for PFAS, the field sampling techniques employed, type of clothing/PPE worn, and materials in the equipment used are all vital to ensure the laboratory delivers the highest quality results, with the lowest limits achievable, in the quickest possible time to satisfy the requirements of your project.

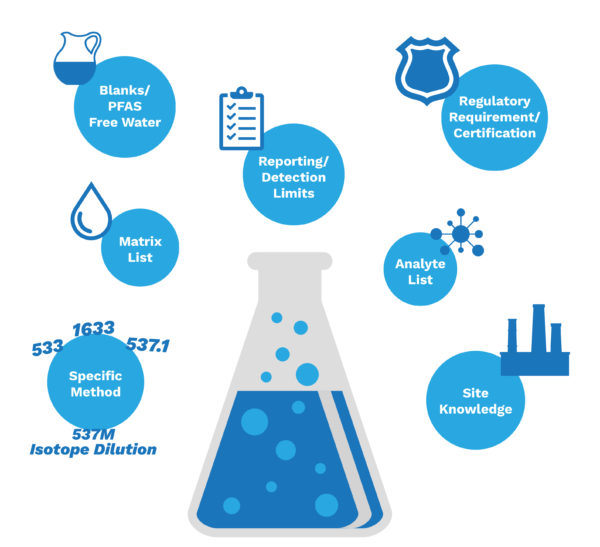

It is important to have as much of the information below in order to determine the best method, accurate pricing and setting realistic expectations regarding delivery time, detection limits and analyte list.

Matrix Type: Drinking water, groundwater, surface water, wastewater, leachate, soil, sludge, sediment, product, AFFF and/or multiphase (does each phase need to be analyzed separately)

Specific Method: 537.1, 533, 1633, 537M (Isotopic dilution), or other proprietary method

Analyte List: PFAS lists are ever evolving; federal and state regulatory programs, as well as certain geographic areas have specific lists ranging from one compound all the way up to 45 plus. Some analytes require their own specific method, so ensuring the correct lists/methods are utilized is vital.

Regulatory Requirement/Certification: DoD, state specific, etc. This will help determine analyte list, method and certification requirements, as well as deliverable package (Level II, III or IV).

Reporting/Detections Limits: The regulatory driver, or data objectives of the project typically determine the required reporting limit (RL) or detection limit (DL). Most are achievable with current technology and best lab practices, but there are times they cannot be met due to matrix interference, dilutions, extraction method (if required) or other anomalies. Informing the lab of the RL/DL needed can usually help the lab report your data in a more timely manner

Site Knowledge: PFAS detection limits are very low, if a sample contains high concentrations, this could impact the laboratory. High concentrations of PFAS can delay results due to laboratory contamination and the necessity for multiple dilutions. PFAS detection limits are very low, if a sample contains high concentrations, this could impact the laboratory. High concentrations of PFAS can delay results due to laboratory contamination and the necessity for multiple dilutions. To limit these delays, ask yourself: Is there a known or suspected PFAS contamination? What is the source? What is the estimated impact (slight, moderate, heavy contamination, single event or multiple)? Understanding the laboratory’s detection limits and what constitutes a high-level sample is important. What may seem low level comparing to other chemicals of concern may be quite high to the laboratory.

Blanks/PFAS Free Water: Do you need Trip, Field Reagent and/or Equipment Blanks? What volume of PFAS free water is needed for rinsates or blanks?

We understand that not all of this information may be available, but the more information that can be ascertained in the beginning, the more helpful the laboratory can be with project initiation and insure the best possible outcome for you.

While the PFAS world is ever changing with new methods, analytes and regulations, the good news is that you don’t have to go it alone. Enthalpy’s two PFAS laboratories and experienced staff are here to assist you.

If you have questions, need more information or would like to request a quote, please contact our El Dorado Hills, CA (1-916-673-1520) location, or our Wilmington, NC (1-910-212-5858) location!

Want our latest blogs in your inbox?

Tell us a little about yourself.