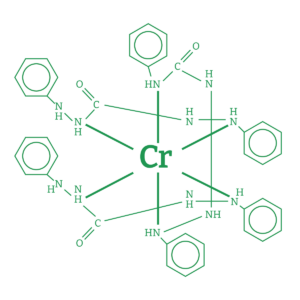

Introduction to Hexavalent Chromium and Method SW-7199

Hexavalent Chromium (CrVI), often referred to as Chromium-6, has garnered significant attention due to its hazardous nature and widespread presence in industrial processes. It has even gained notable media attention from a film based on the story of Hinkley, California, and how Erin Brockovich uncovered the Pacific Gas and Electric Company’s attempt to hide releases of hexavalent chromium into the community’s groundwater.

As it was accurately depicted in the film, this toxic compound poses severe health risks, including respiratory cancer, kidney damage, liver damage, pulmonary congestion, occupational asthma, and skin irritation. These health effects have prompted stringent regulations and heightened awareness surrounding hexavalent chromium since the 1980s. In response to increasing concerns, SW-846 Test Method 7199 was developed for the determination of hexavalent chromium in solids, groundwater, and industrial wastewater effluents. Method SW-7199 offers the ability to detect hexavalent chromium with unparalleled sensitivity.

The Significance of Hexavalent Chromium

A major source of exposure to hexavalent chromium comes from industrial activities in which workers are welding with chromium metal in alloy steel or using pigments that contain CrVI. These industrial processes then cause the release of hexavalent chromium into soil, water, and air which contaminates ecosystems and endangers human health. Hexavalent chromium has been recognized by regulatory bodies such as the Environmental Protection Agency (EPA) and the World Health Organization (WHO) as a potent carcinogen. The EPA included hexavalent chromium in the 3rd Unregulated Contaminant Monitoring Rule (UCMR3) in 2012, illustrating the necessity for CrVI to be rigorously monitored in order to prevent these adverse health effects.

Method SW-7199 at Enthalpy Analytical

Method SW-7199 is renowned for its exceptionally low detection limit. Leveraging state-of-the-art instrumentation and advanced analytical techniques, this method can identify hexavalent chromium concentrations at levels as minute as parts per billion (ppb), surpassing industry standards. This unparalleled sensitivity allows us to detect even trace amounts of hexavalent chromium, enabling proactive intervention and the enactment of risk mitigation strategies.

Experience the Enthalpy advantage with method SW-7199. Our rush capabilities (results are available in as little as 8 hours) are backed by a proven track record (99.8% of data being reported on time or early). Reliable, prompt data delivery empowers you to make informed decisions and meet regulatory requirements with ease. Our team of industry experts are here to make the execution of your testing seamless from sampling to reporting, prioritizing your requirements at every step.

Ready to Take the Next Step?

We take pride in our role protecting the air we breathe, the water we drink, and the soil that feeds us. Our cutting-edge solutions help our clients address their most pressing challenges. With our exceptional capabilities, including a low detection limit and reliable TAT, Enthalpy remains at the forefront of hexavalent chromium analysis. If you’re ready to take the next step, reach out to our knowledgeable team today.