What IS vapor intrusion?

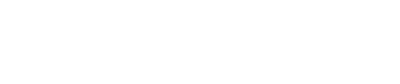

Vapor intrusion occurs when vapor-forming chemicals migrate from a subsurface source into an above-ground building. Essentially, it is when harmful chemicals from soil or groundwater get into indoor air, such as the 1980s Radon basement intrusion scare. In addition to radon, other vapors include:

• Volatile organic compounds (VOCs) such as trichloroethylene and benzene

• Select semivolatile organic compounds, such as naphthalene

• Elemental mercury

• Methane

• Some polychlorinated biphenyls and pesticides

Some of the effects of vapor intrusion vary depending on the type of chemical and the duration of exposure. Vapor intrusion may pose:

- Long term carcinogenic concerns at very low levels

- Blood, brain or liver cancer

- Bioaccumulative properties

- Harm to fetal development

- Respiratory irritation

- Eye irritation, headache and nausea

The integration of vapor intrusion with the same chemicals found in common household products, as well as typical sub-surface urban conditions, make it more likely to misidentify the presence of a compound to equate having indoor air quality problems caused by vapor intrusion. For instance, something as simple as an antiperspirant spray or chemical cleaning compound can produce enough background vapor to significantly skew the results of an indoor air sampling test.

How does a helium shroud operate, and what’s in it?

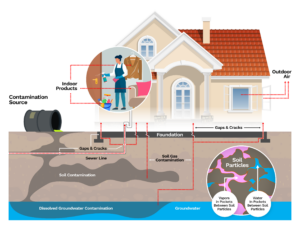

A helium shroud and its typical components are listed below:

- Helium detector(s)

- Soil vapor probes

- Real-time monitors

- Sampling pumps & vacuum chambers

- Portable gas chromatograph

The helium shroud apparatus evaluates ambient leakage during the soil gas collection process. The shroud tests for ambient air leaks around the sample train, and at the soil-gas tubing interface with the ground surface as indicated at the gas tracer. The shroud is positioned over the test area and laboratory grade helium is flooded into the shroud and maintained at a predetermined level maintained during the duration of test and verified at preset times using a helium meter. All readings obtained during the sampling event are recorded and made available for analysis.

The use of Helium as a tracer while sampling is crucial for site clearance for development due to public safety concerns as it provides real time leak detection and sourcing in field. With the issue of a global Helium shortage, it can be difficult to procure with short notice site access permissions. That’s where Enthalpy’s proven helium shroud technology comes in.

What are the benefits of helium shrouds?

Montrose has recognized the materials, financial resources, and time lost by our clients to procuring and operating Helium Shrouds, so we’ve designed our own patented helium shroud technology that:

- Retains twice as much helium

- Conserves time, as we perform multiple nested probes in tandem, 1.5x the output/crew

- Reduces field time by up to 30%

- Provides more on-site mobility and a predictable sampling surface via o-ring and platform approach

Why should you consider a helium shroud?

This technology is ideal for soil vapor sampling technicians, managers, and environmental consultants responsible for modeling vapor intrusion and passage through buildings as part of their Environmental Impact Reports. In the state of California these factors are even more impactful because:

- California accounts for 15% of the people in families experiencing homelessness in the nation

- We have a housing crisis, and the ability to build is becoming bottlenecked by unrealistic risk assessment approaches

- The lack of a standard protocol from any regulatory agency to identify and remove outliers presents challenges in site understanding and long-term monitoring

- Public health stringency in the Bay Area and SF are proactive; Regulatory requirement shifts are setting lower and lower ESL standards

- Other states such as CO, NH, MA, and HI are quickly developing standards and the EPA is in the process of finalizing its vapor intrusion guidelines

- Implications for vapor intrusion guidelines have previously been understudied and are currently being reevaluated.

Are there any drawbacks to using this method?

The main concern most often mentioned about helium shroud testing is regarding the use of laboratory grade vs “party grade” helium. Cost and availability concerns of laboratory-grade helium has led to some testing firms using commercially available tanks commonly used to fill balloons. Compared to the quality control and consistency and purity of the helium in lab-grade tanks, party tanks can be filled from different sources and at different times, leading to sometimes significant variations in the quality of the helium. One common compound often found in higher concentrations in party grade tanks is benzene – in such concentrations that would produce test results with significantly elevated levels. Our patented shroud testing only uses quality tested and verified laboratory-grade helium, so thankfully this isn’t a concern when it comes to our testing.

Where is this technology going?

Helium leak shroud technology can help organizations save money. Without investing in this technology, developers will be forced to:

- Perform long and costly risk assessments that may ultimately yield ownership of land that costs more to maintain than its return

- Implement long-term expensive clean-up programs that do not fully remediate the site or clear it for use

- Invest in technologies that require extensive operations monitoring and maintenance regimens that have no guarantee of timeline, completion, or protection to ever lowering thresholds

Next steps

Vapor intrusion is a very real concern and threat. Helium leak shrouds represent a distinct and viable testing option is accurate and can save valuable resources. To learn more about how we can assist you with your vapor intrusion detection and put our helium leak shrouds to work for you, please reach out.

Will Rice

Will Rice